With global pressure on phasing out environmentally harmful refrigerants, the HVACR world has rediscovered the efficacy of CO2. Hasan S Al-Harahsheh enumerates its many advantages and applications.

With global pressure on phasing out environmentally harmful refrigerants, the HVACR world has rediscovered the efficacy of CO2. Hasan S Al-Harahsheh enumerates its many advantages and applications.

The average global temperature is predicted to rise by between 1.5 and 4.5K in the next 100 years. The principal cause of global warming is the emission of greenhouse gases into the Earth’s atmosphere.

The average global temperature is predicted to rise by between 1.5 and 4.5K in the next 100 years. The principal cause of global warming is the emission of greenhouse gases into the Earth’s atmosphere.

Directly, greenhouse gas emissions occur through the leakage of HFC refrigerants used in refrigeration systems for display and storage of food. These refrigerants have very high global warming potential. CO2 has very low global warming potential compared with conventional HFC systems, which significantly reduces direct emissions. Indirect emissions are also much reduced as the system efficiency is much greater than achieved using conventional HFC refrigeration.

Rediscovering CO2

Over the last 20 years, legislation has prohibited the use of ozone-depleting CFC refrigerants. However, the use of the HFCs is still legal and commonplace. In recent years, natural refrigerants have been proposed as an environmentally friendly solution for the refrigeration industry. These refrigerants, which include ammonia, hydrocarbons and carbon dioxide, do not contribute to ozone depletion and have low global warming potential.

Carbon dioxide offers a long-term solution suitable for many applications in refrigeration and heating, from domestic applications utilising heat pumps to provide hot water and heating to commercial applications for supermarket refrigeration and in industrial refrigeration for many applications.

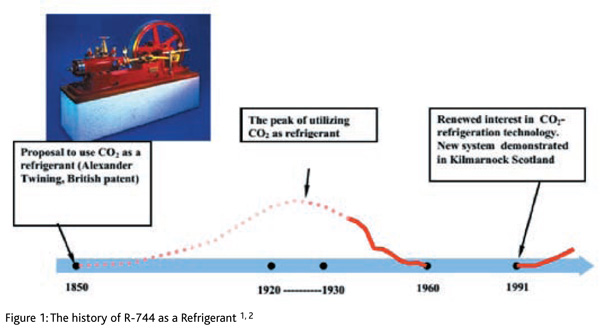

R-744 has been used in refrigeration for many years. Figure 1 shows a timeline detailing its proposal and discovery, decline in the 1930s, to its rediscovery in the 1990s.

Characteristics of R-744

R-744 has 10 noteworthy characteristics:

R-744 has 10 noteworthy characteristics:

Like most natural refrigerants, R-744 is regarded as being environmentally benign. It has an Ozone Depletion Potential (ODP) of zero, and has a very low global warming potential (GWP = 1). The main benefits of R-744 compared to other natural refrigerants are that it is non-toxic and non-flammable – characteristics which often limits the application of other refrigerants. The main characteristics of R-744 as a refrigerant are the critical and triple points.

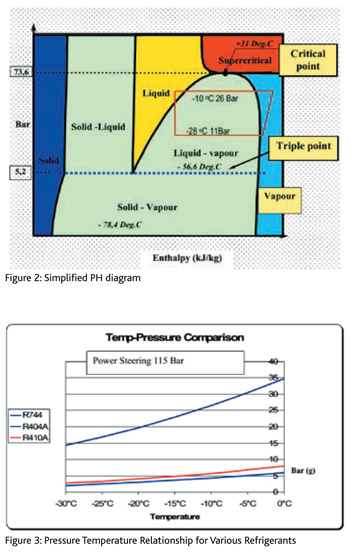

The critical point is a relatively low temperature at 31°C, although at a high pressure of 73 bar. The triple point occurs at -56.6°C with a pressure of 5.2 bar, which is the only common refrigerant to have a triple point above atmospheric pressure. In order to remain below the critical temperature of 31°C it is necessary to use a cascade system to provide a sub-zero condensing temperature. The system restrictions in relation to temperature and pressure can be seen in Figure 2.

Applications and advantages

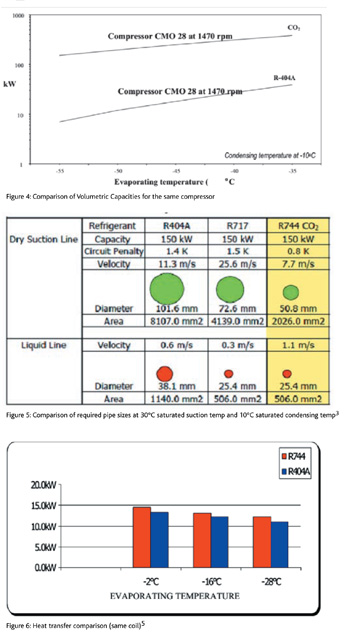

R-744 operates at a far higher pressure than standard refrigerants. However, this is not excessively high compared to similar engineering applications. Figure 3 demonstrates the differences in operating pressures of standard refrigerants and R-744.

R-744 systems have a high volumetric refrigeration capacity, as a result of their very high vapour density when compared to other refrigerants. Consequently, refrigeration compressors using R-744 are six to eight times smaller than those of R22 systems. This can be seen in Figure 4, where the same Sabroe CMO 28 compressor at the same conditions has a far greater capacity when using R-744.

R-744 systems have a high volumetric refrigeration capacity, as a result of their very high vapour density when compared to other refrigerants. Consequently, refrigeration compressors using R-744 are six to eight times smaller than those of R22 systems. This can be seen in Figure 4, where the same Sabroe CMO 28 compressor at the same conditions has a far greater capacity when using R-744.

Further, benefits of high volumetric capacity can be seen when applied to pipe-work. Figure 5 shows the reduction in pipe sizes when using R-744. This will result in a significant reduction in suction line valving costs.

The improved heat transfer properties of R-744 allow the evaporator to be operated at a higher temperature than competitive R-404A evaporators. The literature [4] suggests evaporators may work at 2K higher than conventional R-404A evaporators. The improved heat transfer properties thus result in increased capacity in heat exchangers. The comparisons made in Figure 6 demonstrate a 10% increase in the capacity for the same coil geometry.

The writer is Regional Business Development Manager, Industrial Refrigeration, ME, Johnson Controls Inc. He can be contacted at: hasan.al-harahsheh@jci.com

References

1 Danfoss (2002) CO2 Phase Changes Danfoss [CD Rom]

2 Pearson SF, Development of improved secondary refrigerants Proc Institute of refrigeration Vol. 89, pp65-80 1993

3 Danfoss. CO2 Refrigerant for industrial Refrigeration, Danfoss 2002 Arhus

4 Visser K, Carbon Dixoide for the food processing and cold storage industries AIRAH Natural Refrigerants Conference. Melbourne 2002

5 Palladio software Ver. 3.62 2004 Alfa Laval

6 Sabroe Refrigeration Ltd, 2005 Why is there renewed interest in “old” refrigerants, Sabroe X’s Vej Christian, Hojberg, Denmark.

7 VanRiessen G, NH3/CO2 Supermarket refrigeration systems with CO2 in the cooling and freezing section. The IIR Gustav Lorentzen Natural Working Fluids Conference. Glasgow. 2004

8 Campbell, A, Maidment, GG and Missenden, JF. A Natural Refrigeration System for Supermarkets using CO2 as a Refrigerant. CIBSE National Conference 21-22 March 2006

Copyright © 2006-2025 - CPI Industry. All rights reserved.