Relating from his experience, Peter Tracey broadly outlines the various strategies and measures that can be adopted to control Legionella…

It is worth reminding ourselves of the history of Legionella, or more precisely of Legionnaires Disease, which can sometimes raise its head with disastrous consequences.

Legionnaires Disease can be defined as an acute bacterial infection of the lower respiratory tract with accompanying pneumonia. It was first identified in 1976, after an outbreak of a pneumonia-like illness, following an American Legionnaires Convention in Philadelphia, in the United State – hence the name Legionnaires Disease. The cause was identified as a bacterial organism disseminated by the hotel’s cooling tower. The organism was named as Legionella pneumophila, and since those days over 30 sero-groups, or strains, have been identified. Most commonly associated with outbreaks is Legionella pnemophila subgroup one sub type Pontiac.

Legionella can also cause a milder form of infection, known as Pontiac Fever, which is self-limiting and exhibits flu-like symptoms.

This article is a walk through the over 50 years of experience and an examination of some of the misconceptions about Legionella, which can lead to an outbreak.

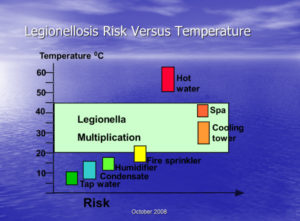

Growth of Legionella

Legionella are found everywhere in Nature but do not pose any danger until a certain set of conditions are met…

Susceptible groups

There are also susceptible groups that are more likely to contract Legionnaires Disease than others. These include…

Conditions that stimulate growth

Certain conditions encourage the growth of Legionella…

This set of conditions contributes to the misconception that Legionella only pose a danger in cooling towers. In fact, the evidence shows that you are more likely to encounter Legionella in hot and cold water services than in cooling towers. This is probably because cooling towers routinely use biocides to kill Legionella. Legionella can also be found in spa pools, decorative fountains and, in fact, in any water system, where bacteria can proliferate and an aerosol can be generated.

Another misconception that is fairly common is that testing water for the presence of Legionella is adequate. This can lead to the mistaken assumption that there is no risk. Testing is a valuable part of the management process but, in itself, is not adequate.

Guidelines and legislation

Guidelines and legislation

The growth in rate of reported cases of Legionellosis (Legionnaires Disease and Pontiac Fever) over the years has prompted ever tightening legislation and updated guidelines from professional bodies, leading to a massive wealth of knowledge on the subject.

ASHRAE, Building Services Research and Information Association (BSRIA), Cooling Technology Institute (CTI) all publish excellent guidelines for the control of Legionella. The CTI Guideline is specific to cooling towers.

The Health and Safety Executive (UK) publishes L8 Approved Code of Practice, along with HSG 274, depending on whether the application is evaporative cooling towers or not. Eurovent issues guidelines regarding evaporative cooling systems.

The Health and Safety Executive (UK) publishes L8 Approved Code of Practice, along with HSG 274, depending on whether the application is evaporative cooling towers or not. Eurovent issues guidelines regarding evaporative cooling systems.

Some manufacturers, including those in the cooling tower business, also issue their own guidelines, but these are often linked to the aforementioned or similar documents.

The most important guidelines are, however, from the authority in which you are working. The Emirates of Dubai and Abu Dhabi have their own guidelines, which should be consulted. All of these take a tried-and-tested, common sense approach to Legionella control.

These all say, in essence, that for control, you need to…

These guidelines are dynamic in the sense that maintenance and review are at the heart of the process. In fact, there is much evidence to suggest that there has never been a Legionnaires Disease outbreak associated with a well-maintained system.

Some methods for bacterial control

An important part of the control process is that of bacterial control. Bacteria cannot be eliminated entirely, as systems are regularly re-infected. A measured approach to controlling bacteria is necessary.

Hot and cold water services

Obviously, in hot and cold water services, extra care must be taken to prevent harm to users compared with more industrial/commercial applications.

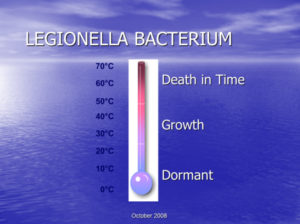

Temperature

In cases where calorifiers are used, raising the temperature temporarily to above 60 degrees will kill Legionella. Care must be taken not to affect end- users, as water at this temperature will scald.

Oxidising biocides

Chlorine and chlorine dioxide are the most commonly used chemicals in hot and cold water services. Due to its ability to penetrate biofilms and its environmental profile, chlorine dioxide is fast becoming the disinfectant of choice in hot and cold

water systems.

Silver and copper ions

Less commonly used is silver and copper ions technology. This has shown effectiveness at controlling Legionella, though.

Ultra-violet (UV)

Ultra-violet light will kill Legionella but must be used close to the point of application, as UV does not impart a residue to the water.

Evaporative cooling systems

There are more options to use in control of Legionella in the case of evaporative cooling systems.

Oxidising biocides

In addition to chlorine and chlorine dioxide, bromine can be used to give effective control of Legionella. Bromine, like chlorine dioxide, is less pH affected

than chlorine.

Non-oxidising biocides

Effective biocides against legionella include isothiazalone, glutaraldehyde, DBNPA and THPS. These biocides work at different kill doses and depend on residence time in the cooling tower.

Some commercial bodies pay close attention to Legionella compliance. These include travel companies, who have a duty of care to their travellers. As international travel is now commonplace, the control of legionella itself becomes more international. Public Health England reports that in 2015 of the 388 cases reported in England and Wales, 46% involved travel outside the United Kingdom. Other interesting statistics were that 75% were male and 80% were over 50 years of age. These grim figures confirm earlier findings regarding susceptible groups.

Peter Tracey is the Business Development Manager – Gulf Region for Feedwater and he can be contacted at peter.tracey@feedwater.co.uk

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the

Copyright © 2006-2025 - CPI Industry. All rights reserved.