In a scenario where a substantial number of water-cooled chillers in the region have started to reach maturity, Dan Mizesko offers two retrofit solutions that meet existing levels of efficiency as well as convert to refrigerants compliant with today’s needs.

Independent chiller specialist companies have developed two retrofit solutions for the industry that will allow you to keep the existing chillers and avoid replacing them with expensive new ones, while modernising them. These are not factory-retrofit solutions that generally lead to a loss of capacity of up to 40% of chiller-rated tonnage. These new solutions will allow the end-users to have no loss in chiller capacity, while helping them move away from currently phased-out refrigerants. It needs to be stressed, of course, that each case will require a full site analysis and testing of the existing chiller’s tubes and shells as well as other data analysis.

The first retrofit solution is a multiple oil-less magnetic bearing compressor replacement of the single or dual existing centrifugal compressors. The second solution is a multiple VFD screw compressor replacement of the existing compressor. I shall now proceed to explain the two solutions.

The first retrofit solution

No centrifugal chiller offered today (even with a VFD installed on the compressor) can operate as efficiently as an oil-less magnetic bearing centrifugal chiller. It offers superior reliability and performance for chiller operation. A retrofit of an existing large tonnage single compressor chiller to multiple oilless magnetic bearing compressor will help operate even more efficiently than the single oil-less magnetic chiller offered today. I recommend installing multiple smaller compressors, which allow substantial savings due to part-load staging of the compressors, as well as larger heat exchanger on the condenser, when operating under lighter loads. This offers large opportunities for additional savings beyond the efficiencies of a single compressor oilless magnetic chiller. Chillers using the variable speed oil-free multiple centrifugal compressors with magnetic bearings offer a rated efficiency in the range of 0.33 to 0.37 KW/tonne (integrated part-load value/IPLV).

History of oil-less magnetic compressor

R&D on new oil-less compressors started in 1993. The design goals for developing a small centrifugal compressor included lubricant-free operation and a direct drive system. The result of these efforts is a compressor that has a capacity of 60-90 tonnes, uses refrigerant R-134a, with magnetic bearings (no oil) and a direct drive system (no gears). Additional benefits include a lightweight design (80% less than traditional compressors) and reduced noise and vibration. By 2001, beta test sites proved that the compressor design was viable for market introduction.

The oil-less design eliminates typical operating problems associated with oil-flooded compressors

The minimum load on the compressor is 15%. The auto balance feature repositions the magnetic bearing 100,000 times a minute to maintain centred rotation at all times. It uses 1.6 amps to start up (elevate the shaft) and operates at 16,000-40,000 RPMs. The motor is a permanent magnet brushless DC motor, and the motor, electronics, and VFDs are refrigerant cooled. The compressor is designed to handle a power outage. The motor becomes a generator.

After the compressor comes to a complete stop, the rotor de-levitates, normally on to touchdown bearings. Should the computer fail, the compressor is designed to handle eight “crashes”. The oil-less design eliminates typical operating problems associated with oil-flooded compressors. Water-cooled units often use flooded evaporators, and any oil in the evaporator tubes will cause a decrease in heat transfer.

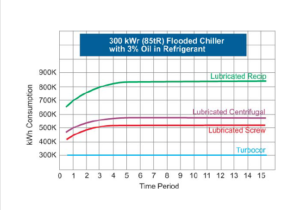

ASHRAE Research Study 601 determined that the vast majority of installed chillers have an excess amount of oil in the cooling system. The systems in the study had between 2.9 and 22.9% of oil in the cooling system. For the purpose of lifecycle cost, it is assumed that 3.5% oil concentration occurs after two years of operation for flooded evaporator systems, and 3.5% of oil in the refrigerant charge reduces system efficiencies by eight per cent.

The chart below demonstrates the ill-effects of oil in the cooling system:

The magnetic bearings and sensors keep the shaft properly centred and positioned at all times. The rotor shaft is held in position with 10 separately controlled electromagnetic cushions, which continually change in strength to keep the shaft centrally positioned. The shaft’s position is monitored with 10 sensor coils, whose signal is fed back to a digital controller. Movements of less than .00002” are sensed and adjustments are made accordingly.

A chiller with five compressors operating at full speed only produces 75 DB of sound at 10 feet – about the sound level of your television

Backup carbon or roller bearings are fitted to catch the shaft and prevent damage, should a control or bearing failure occur. The shaft is monitored and positioned 100,000/sec.

The compressor’s speed adjusts automatically to match the load and current operating conditions so that optimum efficiency is gained. Primary capacity control is done using the on-board VFD, and only uses the inlet guide vanes to supplement VFD controls. IGVs prevent surge conditions at low turndown. IGVs normally operate at 110% position. The slower the compressors, the greater the efficiency; as speed is reduced, energy consumption is reduced.

Chillers with oil-less magnetic technology have virtually no vibration, and the sound is substantially less than any other chiller on the market today. A chiller with five compressors operating at full speed only produces 75 DB of sound at 10 feet – about the sound level of your television. In addition, having five or six compressors allows for much better capacity control and gives the chiller redundancy in the unlikely event of a compressor not being operational.

An oil-less magnetic chiller will allow up to six compressors in one circuit, and provides the ability to use the entire heat transfer surface even when using few compressors, thereby ensuring very close approach temperatures and improved efficiency.

The following is a brief list of benefits of oil-less magnetic bearing centrifugal chillers:

• No oil in the refrigerant system

• No oil in the pump

• No oil in the heater

• No oil in the sump

• No issues of disposing waste oil (considered a hazardous material)

• No oil in the storage requirements

• No oil in the filters

• No oil and filter cost

• No oil analysis required

• No bearing wear/bearing replacements

• No vibration

• No vibration testing required

• Greatly reduced sound

• Exponentially improved efficiency

• Reduced maintenance costs

• Smaller and lighter chiller

• Compressor redundancy

• Water-cooled centrifugal chiller with range of 85-1,200 tonnes, so it is suitable for any chilled water plant, from the smallest to the largest.

If consideration is given to this retrofit solution, I suggest that Eddy Current Testing and inspection is performed on the chiller’s condensers and evaporators, and any defective or rejected tubes be replaced. Also, follow this regimen: Recover the existing refrigerant charge, remove existing compressor and controls, clean the interior shells, and remove any oil and contaminants. Install new control system and oil-less magnetic compressors with all required interconnecting piping, sensors, valves, etc. Evacuate and dehydrate the system and charge virgin refrigerant. Put chillers into beneficial operation and benchmark tonnage and KW per tonne operation. No loss of capacity and increased efficiency will be realised.

One advantage of the screw compressor is that it can deliver high torque at very low speeds

The second retrofit solution

The second solution is a multiple VFD screw compressor replacement of the existing compressor. I am proposing a compressor screw refrigerant retrofit, with today’s new screw compressors with enhanced component tolerances, less oil in circulation, the elimination of metal-to-metal sealing surfaces and balancing component radial forces that contribute to a superior design that maximises compression efficiency, while reducing mechanical vibration and noise, leading to improved performance and reliability. These efficient new screw compressors, combined with the two additions below would result in a very successful chiller retrofit/modernisation.

1. Variable Frequency Drives: Variable Frequency Drives (VFDs) have long been credited with helping reduce the cost of operating pumps, fans and centrifugal chillers. With a screw compressor chiller, VFDs help match the required refrigeration capacity to the compressor output, allowing reductions in motor speed that take advantage of an accompanying reduction in motor horsepower. One advantage of the screw compressor (positive displacement) is that it can deliver high torque (lift) at very low speeds – a factor that creates complications for centrifugal chillers (dynamic compression), resulting in instability or surge.

2. Refrigerant economisers: Refrigerant economisers have been used on centrifugal chillers for a very long time, and are now available for use on the new screw chillers. Through the addition of a brazed plate heat exchanger and Electronic Expansion Valve (EXV) on each refrigerant circuit, the refrigerant is both sub-cooled for additional capacity and diverted to the inter-stage of the screw compressor for increased efficiency. This retrofit solution will also allow conversion of refrigerants without any loss of capacity and offers improved efficiency.

I suggest that Eddy Current Testing and inspection is performed on the condensers and evaporators, and any defective or rejected tubes are replaced. I recommend that this regimen be followed: Recover the existing refrigerant charge, remove existing compressor and controls, install new control system, VFDs, screw compressors, economisers and oil separators, with all the required interconnecting piping, sensors and valves. Evacuate and dehydrate the system and charge virgin refrigerant. Put chillers into beneficial operation and benchmark tonnage and KW per tonne operation. There will be no loss of capacity, and increased efficiency will be realised.

A Carrier 19XR centrifugal chiller on the left, converted to dual screw chiller. The chiller on the right has not yet been retrofitted.

In closing, I must reiterate that additional testing and data analysis need to be performed. However, I am confident that one of the above solutions can successfully be implemented, and will allow the retrofit to perform a refrigerant conversion on almost any existing chiller without any capacity loss and offer increased efficiency performance.

Dan Mizesko is Managing Partner, U.S. Chiller Services Int, HVAC & Energy Services International. He can be contacted at dan@uschillerservices.com.

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Copyright © 2006-2025 - CPI Industry. All rights reserved.