In the fourth part of the series on air filtration, Iyad Al-Attar interrogates if our indoor spaces are designed to prevent the spread of airborne contaminants, and stresses that compromising on residential and hospital indoor air quality is, or should be, unacceptable.

Pollutants in outdoor and indoor air can be irritants, both major and minor. Yet, we are less proactive when it comes to protecting our respiratory systems by choosing the quality of air we breathe. Massive investments go into conducting extensive research and development to provide the latest and the best air filters. But do we give a serious thought to acquire them?

Let us take, for example, the indoor air quality of hospitals. Clean air is a need rather than a luxury when we are hospitalised. Hospitals are considered the most important internal facilities, because numerous and different kinds of end-uses occupy indoor spaces that serve various functions.

The most demanding independent indoor zones are operating theatres. They consist of operating or surgical theatres as well as their interconnecting hallways and working areas. Being in a healthcare facility, patients and visitors have a right to expect hospital indoor air to be of the highest quality, and certainly to be better and safer than air in other types of buildings.

Atmospheric air plays an influential role in introducing additional pollutants, which can come from parking areas, vehicle emissions, ambient traffic and construction activities. Therefore, a hospital could be subject to unacceptable air qualities in certain areas due to intake of toxic compounds from these sources, apart from odours from construction sites around or at the hospital, emissions from light and heavy duty vehicles, as well as harmful compounds present in construction materials. All these contaminants challenge the air filters installed in the hospital’s HVAC system, and their excessive concentrations alter the dynamic performance of the filters.

HOSPITAL INDOOR AIR QUALITY

Not only patients and visitors demand and deserve clean air but also medical personnel who work in these environments on a daily basis. They, too, deserve to breathe clean air, as their well-being and safety are affected by hospital indoor air, as they spend long hours looking after our health and recovery process.

HVAC installations control indoor air quality by virtue of extensive use of air filters. Fresh, pre, fine and absolute filters are utilised to provide the required indoor air quality.

However, owing to the great influx of people and hospital bed traffic into the indoor space, like the waiting rooms, emergency rooms and visitors’ area, contamination possibilities are greatly multiplied, as microorganisms and other contaminants are transmitted indoors. Hospitals, therefore, need to seriously consider upgrading filtration requirements even for areas that are regarded as non-critical spaces of the facility, in order to assure that they have the cleanest indoor air possible. Furthermore, filtration requirements for one-day surgery rooms should not be underestimated and their need for filtration upgrade is absolutely essential.

ABSOLUTE FILTER AND MICROBIAL GROWTH

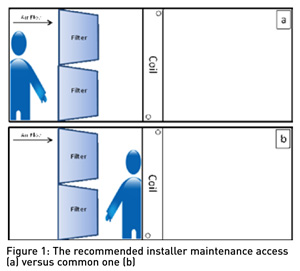

Provided they are appropriately installed, ‘Absolute’ filters can be very effective in encountering microbial growth in HVAC systems. Faulty installation, on the other hand, may contaminate indoor air, causing health hazards. Maintenance personnel, therefore, should have convenient and safe access to the air filter section in an air handling unit. In fact, filter installation should be done by clipping the header filter frame to the installation frame. The installer should stand in front of the dirty/dusty side and not at the back of the clean side of the filter, as shown in Figure 1.

Provided they are appropriately installed, ‘Absolute’ filters can be very effective in encountering microbial growth in HVAC systems. Faulty installation, on the other hand, may contaminate indoor air, causing health hazards. Maintenance personnel, therefore, should have convenient and safe access to the air filter section in an air handling unit. In fact, filter installation should be done by clipping the header filter frame to the installation frame. The installer should stand in front of the dirty/dusty side and not at the back of the clean side of the filter, as shown in Figure 1.

This installation practice prevents the cooling/heating coil from damage, and becomes increasingly important in applications such as pharmaceuticals and hospitals, where absolute filters are used. Air handling unit manufacturers can greatly help in exercising this safe installation measure at the design stage of their units by providing clip-type installation as opposed to the U-channel frame, which is prone to leakage.

Furthermore, the attention of the maintenance crew should also be drawn to the fact that standing behind the clean side introduces unnecessary contamination into the air handling unit from their shoes, uniforms and tools. This would later on require tedious maintenance, cleaning, and most likely, disinfection.

OPTIONS FOR RESIDENTIAL FILTRATION SYSTEMS

If pre-filters are doing their ‘textbook’ filtration jobs well, why then do air diffusers eventually accumulate massive amounts of dust, as shown in Figure 2?

If pre-filters are doing their ‘textbook’ filtration jobs well, why then do air diffusers eventually accumulate massive amounts of dust, as shown in Figure 2?

On a tangential, but relevant note, on several occasions, after my seminars, many people have approached me to enquire about upgrading their existing residential filtration systems. As much as I enjoy spreading awareness of improved indoor air quality, I tell them that unfortunately, a total external static pressure of residential system is not sufficient to install high-efficiency filters. For example, if we consider a residential system (fan coil unit) of around 100 Pa, the total external pressure drop would barely allow about 15 to 20 Pa for the air filter usage. As a rule of thumb, the higher the filtration class, the higher the pressure drop and energy consumption leading to shorter lifetime of the HVAC equipment.

Other practices that could provide higher efficiency of indoor air are the use of self-contained units to clean the air by virtue of several compact filter elements, combining a HEPA and activated carbon filters. While it is difficult to quantify the actual performance of such units, usually filtration is done at the source. In other words, contaminants are required to be removed prior to further introducing the air to the HVAC equipment. Alternatively, modification may be done to the HVAC system to accommodate the pressure drop of the filter used in the upgrade. However, this option has its own limitations and requires ultra-low pressure drop filters.

Clearly, the best option to provide higher indoor air quality is for the filtration and HVAC designers to join hands to combine their efforts and ideas in providing the design that would accommodate in the pre-design stage itself, the filter class needed by the required application. Such a collaboration and cooperation would avoid any retrofitting exercise or individual air cleaning units to be placed randomly in the occupied space.

DESIGN ALTERNATIVES

The issue of design alternatives deserves careful thought. Building owners demand the best components for their air handling units, such as motor and coil. But do they equally pay attention to appropriate selection of the sole line of defence, namely, air filters? Such a line of defence will protect the components of air handling units on which they have spent so much of time and money, and have carefully selected and purchased.

Earlier inclusion of the filtration requirements in HVAC design stage will prove invaluable in terms of providing higher indoor air quality and avoiding the possibility of design modifications after commissioning. Furthermore, the HVAC equipment could provide the capacity to accommodate additional stages of filtration to be used when required. This would be a great option in case of sand storms and in cases of spread of epidemics.

An immediate objection to this option could be the price of higher efficiency filter. In fact, it is a common belief that the cost of an air filter adds significantly to the expenditure, thus burdening the building owner. However, if the overall cost of an HVAC system is considered and compared, the HVAC equipment and its energy consumption constitute the main part of the entire annual bill of the building. Consequently, acquiring lower class (lower cost) filter may have negligible impact in terms of cost savings. In fact, a cheaper filter puts to risk the indoor air quality, has higher pressure drop and shorter life time. By opting for an inferior quality filter, the owners could actually face a situation where their HVAC system becomes the main contamination transmitter across the building. What is even more alarming is that after a certain point, the source of the contamination could be rendered untraceable.

Another associated cost which is often underestimated is the frequent changing and disposing of of the filter. This maintenance measure incurs extra cost, which can be easily avoided by appropriate filter selection.

PREVENTATIVE MEASURES

Low-cost filters may initially appear appealing from the point of view of price. However, it would not only compromise the air quality but also lead to frequent shutdowns and interrupted operation, as frequent maintenance would be needed. In this context, regular visual inspection, monitoring and air sampling could prove to be quantifiable tools in detecting poor indoor air quality.

Proper installations of air filters are highly critical in helping air filters to perform as per expectations. Inappropriate installation, as shown in Figure 3, increases the measure of pressure drop of the filter and affects the overall performance of the air handing unit.

Proper installations of air filters are highly critical in helping air filters to perform as per expectations. Inappropriate installation, as shown in Figure 3, increases the measure of pressure drop of the filter and affects the overall performance of the air handing unit.

Aluminium crimple filters are commonly used in the fresh and pre-filtration stages in the Gulf States. This type of filter comes with the following caveats:

Figure 4 shows concrete evidence of the effects of corrosion of aluminium crimple filters, which are common in humid and seaside installations.

Another important aspect of filtration is providing a leakage-free installation, whether in the pre or final stages of filtration. Leaks within or around the filter defeat the intended purpose of filter installation and negatively affect both the filter performance and its life span. Figure 5 shows two examples of filter leakages for pre and final filters.

Another important aspect of filtration is providing a leakage-free installation, whether in the pre or final stages of filtration. Leaks within or around the filter defeat the intended purpose of filter installation and negatively affect both the filter performance and its life span. Figure 5 shows two examples of filter leakages for pre and final filters.

All of the above measures emphasise the “preventative” aspect of air filtration and the role it plays in providing improved air quality and in protecting the HVAC equipment. What is important to realise is that higher efficiency filters are now available in a more aerodynamic design with lower pressure drop. A great start would be to stop thinking about air filtration as an HVAC accessory and consider it as the sole line of defence of our respiratory and HVAC systems. Our attitude towards air filtration should, therefore, change, so that we begin to regard it as an integrated and influential segment of the HVAC design.

WHERE DO WE STAND?

Combining the knowledge of air filtration and HVAC design is the key to providing solutions engineered to enhance the indoor air quality. But we still need to ask a few relevant questions: Are our indoor spaces designed to prevent the spread of airborne contaminants? Or are the air distribution systems enhancing their contaminant transmission? What can air filtration solutions do to tackle these contamination issues? What precautions can we exercise to prevent our ventilation systems from exposing us to greater risk by circulating a contaminant? No matter what our answers might be to these compelling questions, risking indoor air quality in residential and hospital buildings is simply unthinkable and unacceptable.

Combining the knowledge of air filtration and HVAC design is the key to providing solutions engineered to enhance the indoor air quality. But we still need to ask a few relevant questions: Are our indoor spaces designed to prevent the spread of airborne contaminants? Or are the air distribution systems enhancing their contaminant transmission? What can air filtration solutions do to tackle these contamination issues? What precautions can we exercise to prevent our ventilation systems from exposing us to greater risk by circulating a contaminant? No matter what our answers might be to these compelling questions, risking indoor air quality in residential and hospital buildings is simply unthinkable and unacceptable.

The writer is Regional Director, Middle East, and International Consultant, EMW Filtertechnik, Germany. He can be contacted at iyad.al-attar@emw.de.

Copyright © 2006-2025 - CPI Industry. All rights reserved.