Oliver Javerschek and Dr Günter Dittrich offer an overview of applied standards and a brief introduction to compressor design strategies for compressors

Highlighting how an advanced compressor design influences the application of CO2 with respect to strength and safety, reliability and efficiency, Oliver Javerschek and Dr Günter Dittrich offer an overview of applied standards and a brief introduction to compressor design strategies for compressors for trans-critical applications. They also show how these have been transferred, to a significant extent, to the Bitzer SL compressor series for sub-critical CO2 applications.

Introduction

CO2 is an ongoing trend in refrigeration. Emissions of mostly used HFCs have a 1,430 to 3,922 times higher short-term contribution to global warming than CO2. Therefore, where refrigerant containment is somewhat questionable, CO2 can be a solution for the future. Additionally, it offers the possibility for differentiation from conventional design and a green image. In countries with a high taxation on HFCs, legislation is an additional driving force. Nonetheless, efficiency should not be neglected by introducing a refrigerant with a low GWP, especially because with a low GWP, the efficiency becomes even more important for the assessment of refrigeration systems on the basis of the TEWI method. Besides the efficiency, strength, safety and reliability also require an advanced compressor design.

Advanced compressor design

Considering the thermodynamic properties of CO2, it is obvious that unfavourable conditions with respect to the compressor design appear with higher discharge and gas cooler outlet conditions. These require high discharge pressures and cause low liquid fractions inside the two-phase area after the process of expansion. High discharge and standstill pressures on the suction side are a challenge concerning strength and safety aspects. Another challenge is the reliability of compressors while facing high mechanical loads for the drive gear and lubrication under unfavourable conditions. Also, trans-critical CO2 applications require efficient compressors at full load and part-load conditions, together with a smart system and heat exchanger design, to enable this technology to outperform HFC baseline systems in moderate climate zones. All these highlight the fact that compressors for trans-critical applications require a completely independent design and allow no real synergies to standard compressors. Nonetheless, a good compressor design considers as many proven assemblies from a related compressor range as possible. The development of Bitzer compressors for trans-critical applications with CO2 is based on related compressor models and on two different housing sizes. The types 4PTC, 4MTC and 4KTC are based on the C3 housing, whereas the models 4JTC, 4HTC, 4FTC, 4DTC and 4CTC are based on the C4 body

Strength and safety

The European standard EN 12693 defines the design criteria for commercial and industrial compressors. A safety factor of three can be applied in connection with type-approved relief valves to the atmosphere. Taking a maximum operating pressure (MOP) of 100 bar on the low pressure (LP) side and 160 bar on the high pressure (HP) side as basis, the minimum burst pressures correspond to 300 bar and 480 bar respectively. In other words, the safety margin on LP and HP side is equal to 200 and 320 bar. In order to fulfil these requirements, ductile materials, like spherical cast, have to be applied. Because of different casting processes, molts for grey cast iron cannot be applied.

Concerning the type-approved relief valves, the standard EN 378 has to be applied. Taking the tolerances of the relief valves into account, the standard allows a pressure equal to the MOP multiplied by 1.1, until the maximum flow cross section of the relief valve is available. On the basis of an MOP of 160 bar, the maximum pressure corresponds to 176 bar. To enable the valve to be fully open with this rated pressure, the minimum opening pressure corresponds to 148 bar. The motor limit is 140 bar. Unlike like-type examined safety valves of the systems, type-approved relief valves of the compressors only protect the compressors against bursting, and are allowed to have a lower opening pressure than rated on the nameplate of the compressor.

Reliability

The load conditions for the drive gear of CO2 compressors for trans-critical applications are determined by the characteristics of the natural substance: High pressures and pressure differences, high volumetric refrigeration capacities and remarkable high suction densities. In comparison to standard compressors, for example for the HFC R404A, the suction densities and volumetric refrigeration capacities lead to a compressor design with only small geometrical displacements for a similar cooling capacity at full load conditions at maximum ambient conditions. In this respect, it has to be considered that the ratio of refrigerant mass flow in kg/h per m³/h geometrical displacement is much higher for CO2 compressors.

Focusing on the mechanical loads, the resulting gas forces are dependent on the cylinder bore and the maximum pressure difference. The resulting gas force for the 4NCS corresponds to 11.545 kN on the basis of a maximum pressure difference of 30 bar. The maximum pressure difference for the compressors for trans-critical applications corresponds to 120 bar (20 bar minimum suction – and 140 bar maximum discharge pressure). Therefore, the resulting gas forces correspond to, for example, 16.8 kN for the compressor type 4HTC. The construction of the drive gear contains strengthened connecting rods in the small and big eye to transmit the resulting forces. In order to prevent oval and axial deformation of the piston pins under higher load conditions, they are designed to offer bigger bearing surfaces. A key factor of the design of CO2 compressors for trans-critical applications is the ratio between stroke and bore. It has a significant influence on efficiency and reliability. With respect to the reliability of the compressors, it is of utmost importance to achieve a safe dimensioning in terms of generously dimensioned piston pins, large seating for the piston pin inside the piston and large bearing surfaces inside of the connecting rods. Besides this, the average piston velocity is of importance to minimise the wear. In order to achieve this, larger bores and, consequently, lower stroke-bore ratios are of advantage, because it offers simply more space than a design with longer strokes and smaller bores. The applied stroke-bore ratios for the Bitzer compressors for CO2 applications are under square.

While focusing on the reliability of semi-hermetic piston compressors in commercial applications, the kind of lubricant has a significant influence. Possible candidates for trans-critical applications with CO2 are PVE, PAG and POE. The lubricants have to be evaluated with respect to compressor and system-related issues. With focus on the compressor, hygroscopicity, di-electric strength, material compatibility, resulting viscosities, lubricity and thermal and chemical stability are of utmost importance. Besides the material compatibility, the miscibility with liquid CO2 is relevant for the system design. In the following, POE is considered as the lubricant. With respect to solubility and viscosity characteristics, this choice is the most challenging for the compressor. But it offers advantages for the system design, such as lower hygroscopicity than PAG, better miscibility and improved system oil circulation. The basic viscosity of the considered lubricant corresponds to 85 cSt based on 40°C. An anti-wear package is applied with the oil.

The high gas solubility of CO2 in POE can lead to strong de-gassing effects in connection with rapid pressure fluctuations inside the crank case. These effects occur inside the oil sump, the oil supply channels and on bearing surfaces. Strong de-gassing effects lead to boundary friction conditions, which require adequate measures to avoid severe wear of the drive gear. The pistons are based on standard alloy. During boundary friction conditions, standard pistons cannot provide the requested reliability. Therefore, the pistons are specially treated for improved running qualities. This offers low wear under extreme conditions, for example, start-stop cycling with high liquid fraction in the suction gas. As mentioned above, lower stroke-bore ratios offer the advantage of large bearing surfaces inside the connecting rods. The small eye contains a bearing out of high-performance material. It combines high reliability under high loads and good dry running capability during boundary friction conditions. A multi-layer bearing is applied inside the big eye, which offers extremely good dry running capabilities. The same type of bearing is also applied with the main bearing and bearing inside the bearing cap.

It has been mentioned before that strong de-gassing effects can occur with fluctuating pressures inside the crank case of the compressors. The process of de-gassing is, of course, very much dependent on the amount of CO2 that is solved in the lubricant, and this is dependent on the suction pressure and oil sump temperature. While focusing on the application of variable speed drive (VSD), the resulting oil sump temperature is directly influenced by the resulting mass flows with different speeds. Considering a constant suction and discharge conditions, the oil sump temperature drops significantly with higher speeds. The opposite trend can be investigated concerning the oil carry over rates of the compressors. With higher speeds, and especially with speeds higher than 70 Hz, the oil carry over rate is increased. These aspects have been considered during the development of compressors. However, they cannot be discussed within the scope of this article.

Efficiency

Characteristic values for the efficiency of compressors are the volumetric and isentropic efficiency. The volumetric efficiency is determined by the ratio of effective and geometrical volume flow. The major influences are additional superheating of the suction gas between the suction shut-off valve and the entrance into the cylinder due to motor losses, heat transfer from the cylinder surface and from discharge to the suction side and valve malfunctions. Throttling, friction and motor losses show the biggest influence on the isentropic efficiency of compressors. The isentropic efficiency of the compressor can easily be calculated by the isentropic power input multiplied by the volumetric efficiency and divided by the measured power input at the terminals. Consequently, this value includes all losses. The above-mentioned values can also be described as total “external” efficiencies of a compressor. Indicated efficiencies determine internal losses. The indicated volumetric efficiency is defined as ratio of distance of the indicated volume to the swept volume. Therefore, it describes the loss of useful suction volume due to back expansion and throttling losses. The indicated efficiency describes the ratio of isentropic power input and indicated power input. Energetic losses of the compression process due to leakages, throttling losses and heat transfer processes inside the cylinder can be detected. The indicated efficiencies will not be discussed in detail within this article. However, an indicated p,V diagram will be used to describe the dynamic behaviour of the valves.

In Chapter 3.2 the advantages of smaller stroke-bore ratios for CO2 compressors for trans-critical applications were highlighted. While discussing the pros and cons of a short stroke design, the efficiency also has to be considered. At first view, it seems that the disadvantages for the efficiency are dominant. A short stroke and, consequently, wider bores have the disadvantage of a bigger dead volume inside the cylinder, as well as the tightening line for the piston rings is enlarged, which leads to higher losses along the piston. Süss [1] proposed longer strokes in his study to reduce the leakages along the piston.

Another approach was considered for the design of the compressor types 4PTC to 4CTC in order to compensate the disadvantage with respect to the volumetric efficiency of a shorter stroke. The pistons are equipped with three piston rings. This solution ensures a reduction of the leakages along the piston. Besides this, the triple piston ring solution provides a moderate pressure reduction with each stage, and leads, consequently, to a reduced load on each piston ring. This increases the lifespan. Of course, the piston rings are also optimised for reduced friction to minimise losses with respect to the isentropic efficiency. Further, with respect to the volumetric efficiency, the dead volume of the compressor models is reduced to a minimum by observing high safety. The advantages of wider bores with respect to the flow cross sections of the valve plate are obvious. The available space is used to design the flow cross sections and valve positions in an optimum way. The Bitzer compressor range for trans-critical applications with CO2 is designed for VSD in a wide range. In order to minimise throttling losses, not only at rated speed, but also with speeds greater than 60 Hz, flow cross sections must be designed accordingly. With higher mass flows, the flow velocities are increased and the influence on the pressure drop is quadratic. Throttling losses lead to a lower indicated efficiency of the compressor. The available space is also utilised to apply an optimised valve design, which combines efficiency and high reliability. As a result, a delayed closing of the suction working and discharge working valves is prevented, and leakages through the valves are minimised as well. Both malfunctions could reduce the indicated volumetric efficiency of the compressors, but are avoided with the described design.

The motor cooling of the compressor models for trans-critical applications is realised by suction gas. By applying suction gas cooling, a balance point between necessary and excessive motor cooling has to be found. A suction bypass or low effects on motor cooling by the suction gas lead to the requirement of heat rejection through external oil cooling or cooling by ambient air. Too much motor cooling leads to very low oil sump temperatures caused by the extremely good cooling effect of CO2, and to unnecessary high superheating of the suction gas with losses in terms of volumetric efficiency.

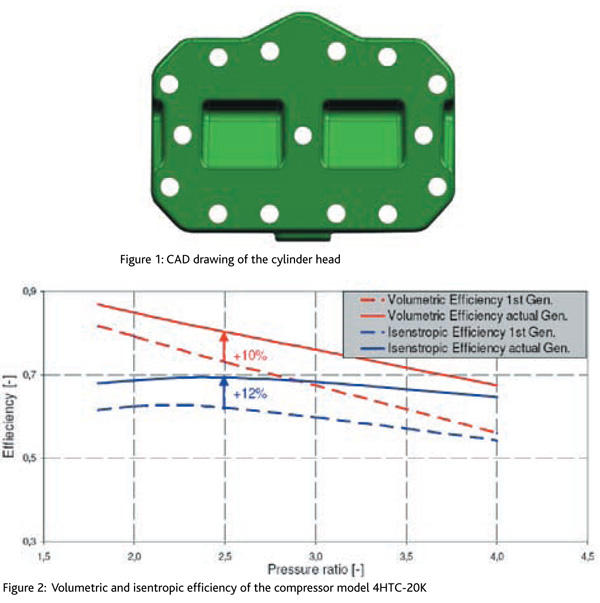

Due to internal measures inside the motor compartment, the stream of suction gas is divided with the discussed compressor models. Internal channels ensure that a rated amount of suction gas bypasses the motor. Internal channels lead the suction gas directly to the suction chambers. A sufficient motor cooling is provided by the amount of suction gas that streams along the stator. Due to this measure, high volumetric efficiencies can be achieved, and external measures for the motor and oil cooling do not have to be applied within the wide application range of the compressors. In order to minimise the heat transfer from discharge to the suction side at the cylinder heads, the assembly shows a new design. As shown in Figure 1, the suction and discharge chambers are separated. The reduced heat transfer results in further improved volumetric and isentropic efficiencies.

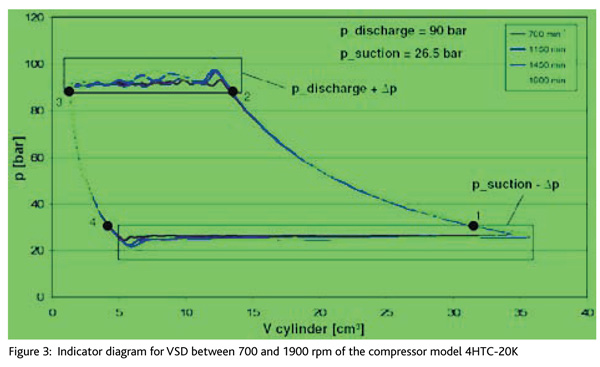

Characteristics of the volumetric and isentropic efficiencies for the compressor model 4HTC-20K are provided in Figure 2. It shows a comparison of the first generation and the actual design. It defines the efficiencies on the basis of a constant suction pressure of 28.0 bar and a suction gas superheat of 10 K; the pressure is equal to -8°C saturated suction temperature. Efficiencies are given for head pressures from 50 bar to 112 bar. 50 bar equals a condensing temperature of 15°C and 112 bar corresponds to a optimum discharge pressure for a gas cooler outlet temperature around 45°C.

During the development of the compressor, the volumetric efficiency was improved significantly. On basis of a pressure ratio of 2.5, which equals a discharge pressure of 70 bar, an increase of 10% could be achieved. From the beginning, the cylinder heads featured separated suction and discharge chambers. With higher head pressures, which are typically for high discharge temperatures and a higher power input of the motor, the discharge temperatures show higher values as well. Consequently, the suction gas between the suction shut-off valve and the suction chamber is influenced by higher waste heat of the motor and heat rejection from the heated cylinder walls and from the discharge side. The characteristics of the volumetric efficiencies show that the thermal load of the suction gas could be further reduced during the development. Also, the working valves were optimised during the development. Besides the volumetric efficiency, the isentropic efficiency could be improved significantly as stated in Figure 2. An increase of 12% could be achieved for a pressure ratio of 2.5. Throttling and friction losses were reduced during the development. Taking a maximum gas cooler outlet temperature of 35°C and a discharge pressure of 90 bar into account, the pressure ratio corresponds to 3.2. Further, considering a condensing temperature of 15°C, the total isentropic efficiency of the discussed compressor model is always clearly above 0.65. This enables an efficient operation of the compressor throughout the seasons and leads to high values for the SEER.

The fact that the isentropic efficiency shows such a flat characteristic is typical for a piston compressor. The dead volume contains a certain amount of refrigerant. With the down motion of the piston, back expansion occurs and forces the piston down. Transmitted via the eccentric shaft, this fact reduces the necessary torque for the piston that moves up. Trans-critical applications with CO2 require efficient compressors under all operating conditions to reach similar or higher COPs than HFC baseline systems in moderate climate zones.

Detailed investigations on the indicated work of the compressors were performed during the development and optimisation of the compressors. Figure 3 shows an example of a p,V diagram measured with the compressor model 4HTC-20K.

The function of the working valves was investigated in connection with VSD at constant suction and discharge conditions. All measurements are based on 26.5 bar suction and 90 bar high pressure, a suction gas superheat of 10 K and compressor speeds between 700 and 1900 rpm. Shortly after passing the lower dead centre, the piston moves upwards (1). The diagram demonstrates that the compression lines (1) to (2) with various compressor speeds are almost identical. Therefore, it demonstrates that the closing behaviour of the suction valves is good under various mass flow rates. The exhaust stroke is shown between (2) and (3). The various characteristics show a certain deviation concerning the over compression.

It is self-evident that certain pressure differences between discharge and high pressure are necessary for unloading the cylinder and discharging into the high pressure chamber of the cylinder head. The measured pressure differences are in the range of three to 11 bar between 700 and 1900 rpm. At the upper dead centre of the piston, the discharge valve closes and as soon as the piston starts to move down again, back-expansion takes place between (3) and (4). The remaining gas inside the dead volume of the cylinder expands back to suction pressure (4). The almost identical characteristics prove a good closing behaviour of the discharge valves. The pressure differences between the opening pressures of the suction valves and the suction pressure are stated between (4) and (1). The differences are in the range of two to six bar between 700 and 1900 rpm.

The indicator diagram highlights that the working valves are designed to an optimum for the application of VSD. A Malfunction like a delayed closing of the valves does not occur. While assessing the discharge and suction characteristics in Figure 3, it has to be considered that working valves have a certain inertia. The mechanical inertia and the spring force of the working valve result to a resistance that acts against the opening force. With higher compressor speeds and consequently higher mass flows and flow velocities, the resistance is increased as well. A higher force leads to higher pressure differences for the opening and closing of the working valves. An additional effect shows the oil on the valve seats that causes an adhesive bonding effect. Besides investigations for different compressor speeds, tests were carried out for various head pressures as well. However, within the scope of this article, all aspects of the development and the optimisation of the compressors for trans-critical applications cannot be illuminated.

Conclusions

Compressors for trans-critical applications with CO2 require demanding techniques with the respect to strength and safety, reliability and efficiency. By applying innovative ideas and new technologies, the mentioned compressor models for trans-critical CO2 applications have reached an advanced level of engineering. The compressors feature no external piping, suction gas cooled motors without the requirement for oil cooling, offer high efficiencies and very favourable operating characteristics with low vibrations and pulsation due to four-cylinder design. From the application engineering point of view, the compressors are designed to withstand challenging operating conditions, like wet operation and boundary friction conditions. The compressors are designed for VSD in a wide range and combine high reliability with superior efficiencies.

NOMENCLATURE

BIBLIOGRAPHY

1 Süß J. 1998, Untersuchungen zur Konstruktion moderner Verdichter für Kohlendioxid als Kältemittel, DKV Forschungsbericht Nr. 59:

Oliver Javerschek is a Project Manager at Bitzer Rottenburg

Günter Dittrich is the Former Head of Development, Piston Compressors

They can be contacted at mail@bitzer.ae

Copyright © 2006-2025 - CPI Industry. All rights reserved.