A combination of evaporative cooling cycles enables cooling below the wet bulb temperature of air, thus addressing the most pressing challenges of our times – decarbonisation, says Vinod Ramnani of ATE Enterprises

In our engineering science studies, we were taught it is theoretically impossible to cool below the wet bulb temperature of air by evaporating water. It is no surprise that the majority of us find it hard to believe there exists a combination of evaporative cooling cycles by which it is not only possible to cool “below the wet bulb” temperature of air but also has been successfully deployed in numerous applications. Let us understand how we can use these cycles to help address the most pressing challenge of our times – decarbonisation.

To understand the possibilities better, a few concepts should be understood…

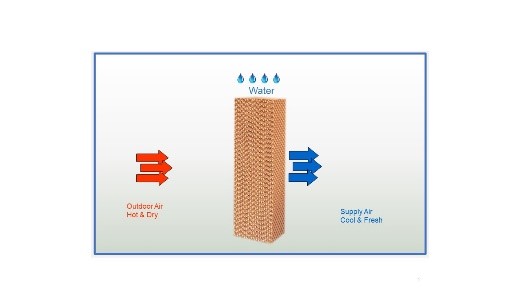

Direct evaporative cooling – DEC

Direct evaporative cooling lowers the temperature of air by using the latent heat of evaporation, changing water to vapour. Warm dry air is changed to cool moist air. Heat in the air is used to evaporate water. Since no heat is added or removed, this is an adiabatic process. The enthalpy of the air – or energy of the air – does not change. Such direct evaporative systems vary from being 70-95% effective in temperature reduction related to the incoming air’s wet-bulb temperature.

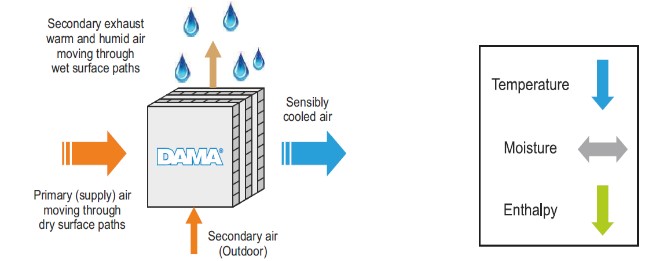

Indirect evaporative cooling – IEC

IEC is performed in a heat exchanger. Thermodynamically, an indirect evaporative cooler passes primary or product air (supply air) over the dry side of the heat exchanger and secondary or working air (scavenging air) over the wet side of the heat exchanger. The wet side absorbs heat from the dry side to evaporate water and, therefore, cools the dry side with the latent heat of vaporising water into the air. The scavenging air that facilitates the vaporisation is exhausted out. The primary air is cooled without any addition of water; and thus, it becomes a purely sensible cooling process.

This process is indicated below for a plate type heat exchanger.

The supply air stream on the dry side of the plate travels in cross flow to the scavenging air on the wet side.

The effectiveness of these types of coolers is reported to approach 85% of the incoming air wet bulb temperature when the difference between air dry bulb and wet bulb temperature is more than 15 degrees C.

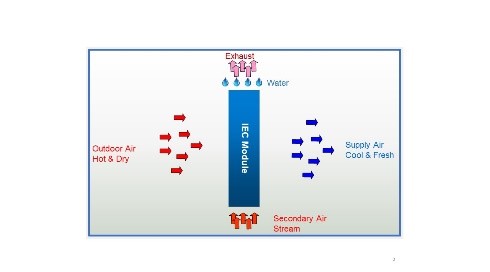

Indirect and direct evaporative cooling – IDEC

Combining both the above cycles – that is, indirect and direct evaporative cooling – IDEC – an effective cooling process emerges which achieves significantly better results and sub wet bulb cooling. The product air (supply air) temperature on the dry side of the plate easily reaches below the wet bulb temperature of the incoming air at the end of two cycles.

Adaptive cooling and ASHRAE Standard 55

Applications of Indirect Evaporative cooling

Sub wet bulb temperature (SWBT) evaporative cooling: IDEC

The SWBT evaporative cooling system operates on the principle of two stage “indirect + direct evaporative air conditioning – IDEC”, comprising of air pre-filters, blower, water distribution system, sensible heat exchanger (IEC) and an adiabatic heat exchanger constructed of cellulose or equivalent type of cooling pads employed to evaporatively cool the treated air after IEC.

Let us look at what kind of cooling temperature of air can be achieved with the above arrangement with two stages (Indirect + Direct) cooling in dry and semi-humid conditions.

Let us take Riyadh (hot and dry), and Dubai (hot and humid) cities for the analysis.

Riyadh:

| Ambient temperature as per ASHRAE | Temperature achieved after first stage (IEC) | Temperature achieved after two stages (IEC+DEC) | Water consumption (per 1,000 CFM) |

| Max DBT: 44.9 degrees C and co-incident WBT: 19.5 degrees C | 24.60 degrees C/12.2 degrees C | 13.40 degrees C/13.2 degrees C | 22 LPH |

| Max WBT: 37.7 degrees C and co-incident DBT: 21.4 degrees C | 24.7 degrees C/17.27 degrees C | 18.00 degrees C/17.27 degrees C | 14 LPH |

Dubai:

| Ambient temperature as per ASHRAE | Temperature achieved after first stage (IEC) | Temperature achieved after two stages (IEC+DEC) | Water consumption (per 1,000 CFM) |

| Max DBT: 43.3 degrees C and co-incident WBT: 23.6 degrees C | 27.50 degrees C/19.0 degrees C | 19.80 degrees C/18.03 degrees C | 16 LPH |

| Max WBT: 35.4 degrees C and co-incident WBT: 30.0 degrees C | 32.2 degrees C/29.73 degrees C | 30.0 degrees C / 29.73 degrees C | 5 LPH |

In addition to the above, these systems will significantly save power consumption vis-à-vis air conditioning systems in dry climates by more than 70% and in humid climates by nearly 45% during peak summer conditions.

Further, in comparison to air conditioning, which is predominantly recirculated air system, these systems (operating on the adaptive comfort principle) are 100% fresh air systems, resulting in significantly better Indoor Air Quality (IAQ).

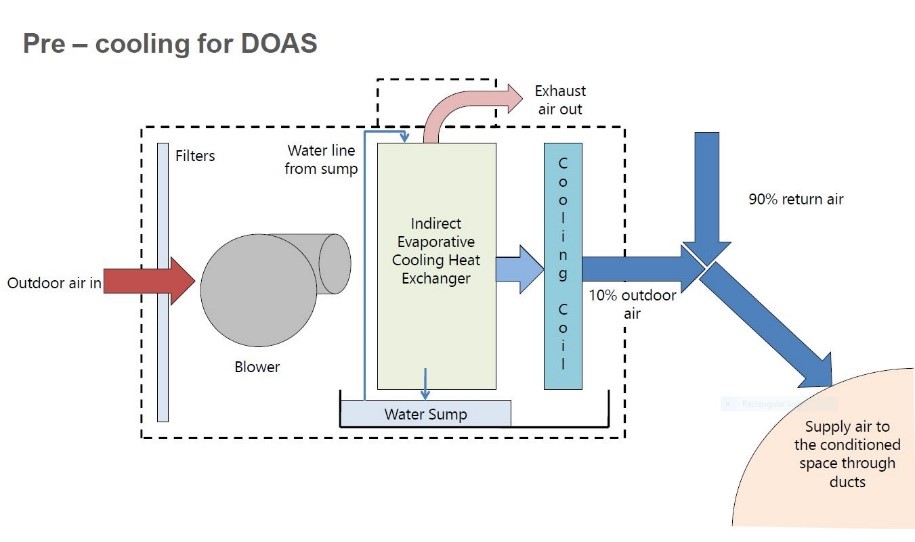

Adopting IEC for pre-cooling of fresh air for centrally airconditioned buildings

Introducing treated fresh air into conditioned spaces with pre-cooling by Indirect Evaporative Cooling (in lieu of heat wheels) saves power, as heat wheel does not provide the following distinct advantages.

With increased focus on retrofittable decarbonisation, it is time we look at this alternative indirect evaporative cooling technology seriously.

With distinct advantages of power savings, excellent IAQ (100% fresh air system) and applicability of indirect evaporative cooling in humid and tropical climates, indirect evaporative cooling-based systems deserve to be considered for various applications, including industries, warehouses, religious places, sports arenas and outdoor air cooling. In short, it deserves a prominent place in contemporary high-performance buildings.

The writer is General Manager – Business Development, ATE Enterprises/HMX. He may be contacted at vinod.ramnani@hmx.co.in.

Copyright © 2006-2025 - CPI Industry. All rights reserved.