Dr Iyad Al-Attar explains the importance of defining critical parameters, such as particle size, which affect the performance of air filters. He also strongly advocates the view that we need to take strides in the field of air filtration today to make a positive impact on the health of generations to come.

Aerosols influence our daily lives through the role they play in the chemistry of the atmosphere. Aerosols are defined to be liquid or solid particles suspended in a gaseous medium long enough to be observed and measured, generally about 0.001 to 100 µm.1 Their ability to impair visibility and penetrate into the deepest segments of the respiratory system makes them capable of causing health hazards. Silicosis, for example, is an occupational lung disease caused by inhaling silicon dioxide (silica) dust, usually in crystalline form as quartz.2 There is an abundance of Silicon (Si) in the earth’s crust, as it is the second most common element next to oxygen. Generally, the effect it has on our health depends on the dose and the type of dust inhaled, the size of particles reaching the lungs and exposure time in the dusty environment.

Particle size in engineering terms

Once again, as has been reiterated in this series, the size of the particle is of importance. Particle size is regarded as a crucial parameter is every aspect of Aerosol Science. However, in order to quantify aerosol effects on human health, it is essential to enhance our understanding of the atmospheric aerosols properties, specifically particle size. The first step towards building a solid knowledge in aerosol filtration, is establishing engineering definitions to the significant parameters influencing the process at hand. While particle diameter stands as the greatest nominee since it has several definitions depending on the criteria at which it is defined, other parameters, such as particle density, concentration and shape are equally important and need to be given due attention.

Clearly, an important parameter to be addressed is the location of dust deposition in the lung, which largely depends on the particle size. Motion descriptions of airborne particles require a definition to encompass their often irregular shapes. But the question is, can such a definition make particle size describable in engineering terms?

Aerodynamic diameter versus Stokes’ diameter

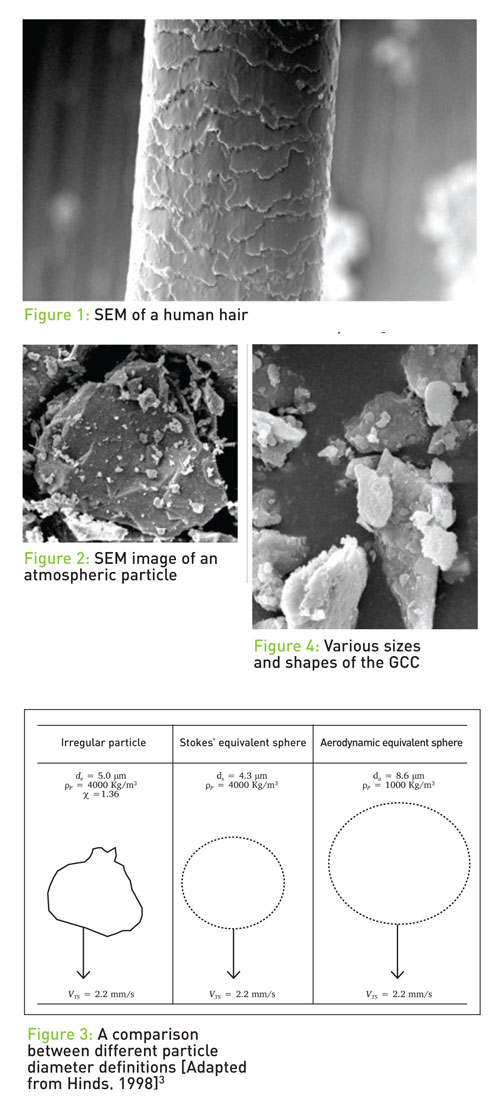

Particle size or diameter is usually associated with our perception of spherical particles and our sight limitation down to a human hair (See Figure 1) or a cloud of smoke [50-100µm]. Particle diameter measurement is critically an important parameter in filtration and in other fields. In general, particles have irregular shapes (See Figure 2) with actual geometric diameters that are difficult to measure. However, when considering irregular geometries of particles, an equivalent diameter that can be physically determined to characterise the particle property and behaviour is required. A common description of the particle diameter is the aerodynamic diameter, which is a physical property of a particle in a viscous fluid, such as air.

Aerodynamic diameter is an expression of a particle’s aerodynamic behaviour, as if it were a perfect sphere with unit-density and diameter equal to the aerodynamic diameter. Such a model has the same terminal settling velocity. Aerodynamic diameter is commonly applied to particulate pollutants and inhaled drugs to predict where in the respiratory tract such particles will get deposited.

Another related diameter is Stokes diameter ds, which is defined as the spherical particle that would have the same density and settling velocity (VTS) as the particle. The Stokes diameter is less common and the Aerodynamic is widely used to represent the particle diameter. Figure 3 illustrates the differences of particle diameters.3

The performance of air filters is highly affected by particle size, and its distribution. Particle size, shape and density can determine the dominating filtration mechanisms. Figure 4 shows various sizes and irregular shapes of atmospheric dust particles existing in the GCC atmosphere.

Dust cake formation – filter clogging

When filter fibres collect dust particles and, then, particles collect one another, a dust cake is formed. A dust cake acts as another layer of filtration, and with time, its great fragility and variable thickness makes the filter performance analysis more complex. Therefore, knowledge of dust cake properties, such as particle size, dust cake porosity and permeability are imperative for better prediction of the filtration performance.4,5

Filter clogging is the last stage of the lifespan of a filter, and is also highly affected by particle size. Therefore, particles of different sizes, shapes and phases are a major point of interest for researchers in the air filtration field, since it allows designers to determine the lifetime and the pressure drop at which the filter should be replaced. The filter structure may change internally if particles deposit within the media, or externally if particles deposit on its surface to form a new layer of dust. Such a change in structure affects the pressure drop response of the filter, which also depends on air velocity. As far as the size of the particle is concerned, finer particles cause higher pressure drop and are considered more clogging than larger particles.

Reducing particle concentration – ventilation and filtration

When we think of improving the Indoor Air Quality, typically, our focus merely shifts towards air filtration. However, ventilation is another means used to reduce particle concentration by either supplying air to or removing air from an indoor space with the intention of controlling air contaminant levels, humidity or temperature within the space. Ventilation is considered to be one of the most common engineering mechanisms used to control emissions, exposures and chemical hazards in the work environment.

It is absolutely essential in many applications, both residential and industrial, to install air filters for several reasons. Initially, air filters protect the HVAC equipment and provide improved Indoor Air Quality for human occupants. Further, filtration is application-specific, providing certain cleanliness to meet the requirement of each application. In installing filtration stages, particle concentration is reduced, which will have a great impact on the system performance at hand. The reduced concentrations of particulates in indoor air have a great impact on human health and productivity.6

Conventional wisdom

Conventional wisdom tells us that in order not to pass judgement, facts need to be gathered. By the same token, prior to making any air filtration selection, fundamental knowledge on the subject needs to be gathered. This article has addressed how important it is to define critical parameters, such as particle size, which affects the performance of air filters.

It would certainly be an endless list, if I were to enumerate the names of the great scientists, chemists and engineers who spent their lives researching Aerosol Science and working towards its advancement. The technology brought about in the light of their findings and the underlying theories they established are being taught in universities worldwide. However, a compelling question remains: Are we endorsing or even suggesting any scientific initiatives that can be taken today to make advancements in the field air filtration science, technology and research to positively impact generations to come? As a corollary, are we building on the great advancements made by the pioneers in the field? Although there is so much more that needs to be done in the field of aerosol filtration, collaborative endeavours could be the first step in the right direction towards bringing our far-reaching goals, within our reach.

The writer is Regional Director, Middle East, and International Consultant, EMW Filtertechnik, Germany. He can be contacted at iyad.al-attar@emw.de

A tribute to aerosol scientistsLooking back at the historical achievements made by science in the past two centuries, we would certainly be remiss if we do not acknowledge the names of great scientists who shone the light of learning to eradicate ignorance, and laid the foundations of aerosol science. A deserving applause goes to John Aitken (1839-1919), a Scottish meteorologist, physicist and marine engineer, who was one of the founders of Aerosol Science and builder of the first apparatus to measure the number of dust and fog particles in the atmosphere. In 1959, air filtration by fibrous filters was one of the main branches of aerosol research organised by Prof Nikolai Albertovich Fuchs (1895-1982) in the Karpov Institute of Physical Chemistry in Moscow. Fuchs’ name is associated with the establishment and the advancement of aerosol filtration, through his ability to theoretically interpret results of experiments. He was the founder of the Aerosol Science in Russia and an important cofounder of this scientific discipline globally. I strongly doubt if there is a single aerosol physicist, chemist or engineer who is not familiar with the great contribution of Prof Fuchs to the field of Aerosol Science. His book, The Mechanics of Aerosols stands tall as a great reference work in libraries worldwide.1, 7, 8 |

REFERENCES

1 Analytical chemistry of aerosol, edited by Kvetoslav Rudolf Spurny, Lewis Publisher, 1999.

2 Pathology by Rubin, John L Farber, MD (Editor), Emanuel Rubin (Editor), [1988]. Lippincott Williams & Wilkins.

3 Hinds WC, 1998. “Aerosol Technology”, Wiley, New York.

4 Schmidt E, 1997. “Theoretical investigations into the compression of dust cakes deposited on filter media”, Filtration & Separation, 34(4), 365-368.

5 Neiva ACB and Goldstein L Jr, 2003. “A procedure for calculating pressure drop during the build-up of dust filter cakes”, Chemical Engineering and Processing, 42(6), 495-501.

6 Fisk W and Rosenfeld A, (1997), “Improved productivity and health from better indoor environments”, Center for Building Science Newsletter, Lawrence-Berkeley Labs.

7 Advances in aerosol filtration, edited by Kvetoslav Rudolf Spurny, Lewis Publisher, 1998.

8 Fuchs NA, 1964. “The mechanics of aerosols”, Pergamon, Oxford.

IMPORTANT NOTE: Unless otherwise referenced, the images used in this article are copyright of the author.

Copyright © 2006-2025 - CPI Industry. All rights reserved.