The contributions of the paint and powder coatings industry towards Green Building and energy-efficiency efforts have gone a long way in delivering benefits, with heat reflection being one of them, says Yulia Gvozdeva

The contributions of the paint and powder coatings industry towards Green Building and energy-efficiency efforts have gone a long way in delivering benefits, with heat reflection being one of them, says Yulia Gvozdeva, and supports her view with empirical instances.

Urbanisation, which refers to the increasing number of people residing in urban areas, has now become a global trend with almost half of the world already living in cities and towns. In fact, the United Nations (UN) has forecast that by 2050, 70% of the world’s population will be living in urban areas.

Heat Island Effect

With this figure in mind, one can just imagine the amount of energy needed. Modern cities consume about 75% of the energy, while at the same time producing 80% of carbon emissions. They are also responsible for the Urban Heat Island (UHI) effect – when temperature in industrialised cities becomes significantly warmer as compared to nearby surrounding rural areas. This phenomenon is mainly caused by decreasing vegetation and low reflective power of urban surfaces, and also leads to an increase in cooling and energy costs.

A unified approach

Looking to address this, industry and governments around the world have started to design and implement Green Building initiatives and standards. This unified approach has paved the way for the adoption of Green Building rating systems like LEED, Green Star, Estidama and BREEAM among others. Dubai, for example, initially introduced Green Building regulations and specifications as a voluntary practice in 2011, but has now made it a standard application for all projects. Another example is Abu Dhabi’s Estidama, which is the Arabic word for sustainability. The programme provides a strong framework that is mandatory for all new buildings, and has been in use since 2008 across a variety of projects. Estidama is part of the Plan Abu Dhabi 2030 vision of further developing the UAE capital according to innovative green standards. Other examples of this global drive include Singapore, where it has become mandatory for public projects to obtain a high environmental rating set by the country’s Building regulations. As part of the move towards increased compliance, some governments offer strong incentives to encourage private investors and developers to contribute.

Reflecting the strong commitment towards sustainability, the Gulf region has already seen successful execution of green projects like Masdar City in Abu Dhabi (the world’s first carbon-neutral city); the DEWA building in Dubai’s Al Quoz area with the LEED Platinum rating and the King Abdullah Financial District in the Kingdom of Saudi Arabia, which is set to become the world’s first LEED-certified district. The UAE’s confidence in shifting towards Green Building compliance remains strong, and has prompted industry analysts to predict that by the year 2015, 60% of the country’s construction projects will be green.

Building materials sector – evolution of green strategies

The building materials sector has been tagged as one of the most dynamic segments in developing and introducing technologies that help to deliver more sustainable construction projects. Commendable as it is, companies in this sector have actively invested in implementing their green strategies and have directed their R&D activities towards eco-friendly and more efficient solutions. The paint and coating industry has been quite active in the move towards sustainability, having introduced a wide range of green solutions that are now used all over the world.

The industry has placed great importance on the move to reduce Volatile Organic Compounds (VOC) which represent a large variety of chemicals like aliphatic and aromatic hydrocarbons, alcohols, aldehydes, ketones, esters, and halogenated compounds.

One of the main concerns associated with indoor exposure to VOCs is their potential negative effect on the health of building occupants (sensory, irritation, toxic as well as increased risk of cancer due to exposure to benzene), whereas outdoor VOC emissions contribute to formation of ozone, a constituent of photochemical smog. The increasing presence of VOCs in indoor and outdoor environments can be attributed to the fact that they have become essential ingredients in many products and materials.

Efficacy of powder coatings

To counter this, powder coatings are now widely used across many types of surfaces. In fact, it is now actively specified for plant treatment of aluminium extrusions, claddings and steel elements that are used on façades, roofs and inside buildings. These products have been developed primarily for corrosion protection and for adding decorative effects to the metal components of buildings.

Powder coatings make use of a dry factory application process and contain no solvents releasing negligible amounts of, if any, VOCs into the atmosphere, making powder coatings a highly environmentally friendly technology.

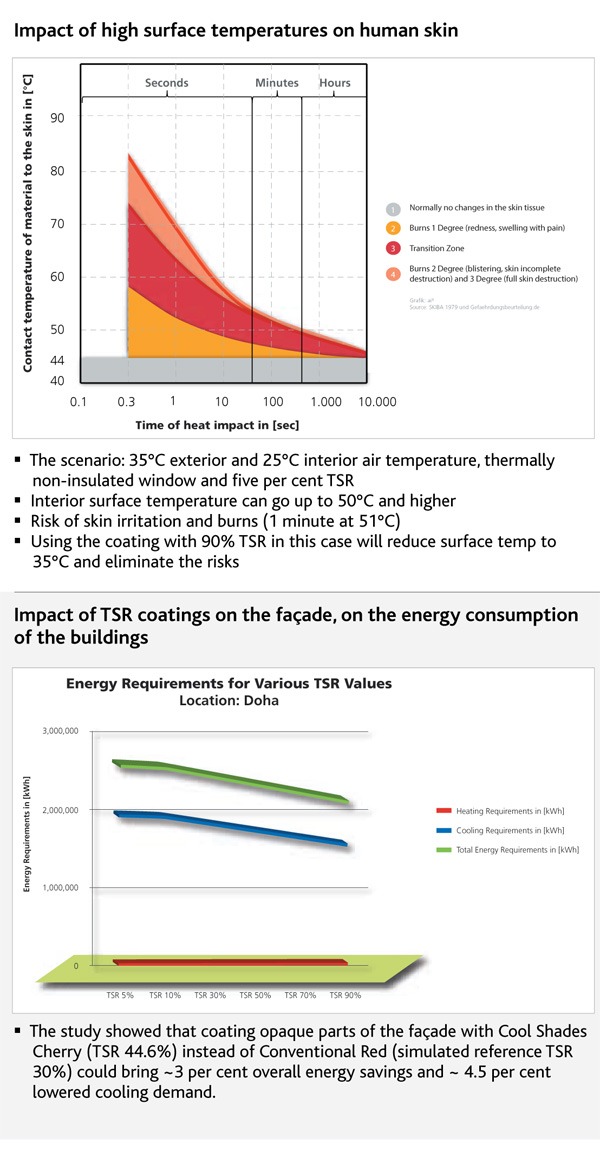

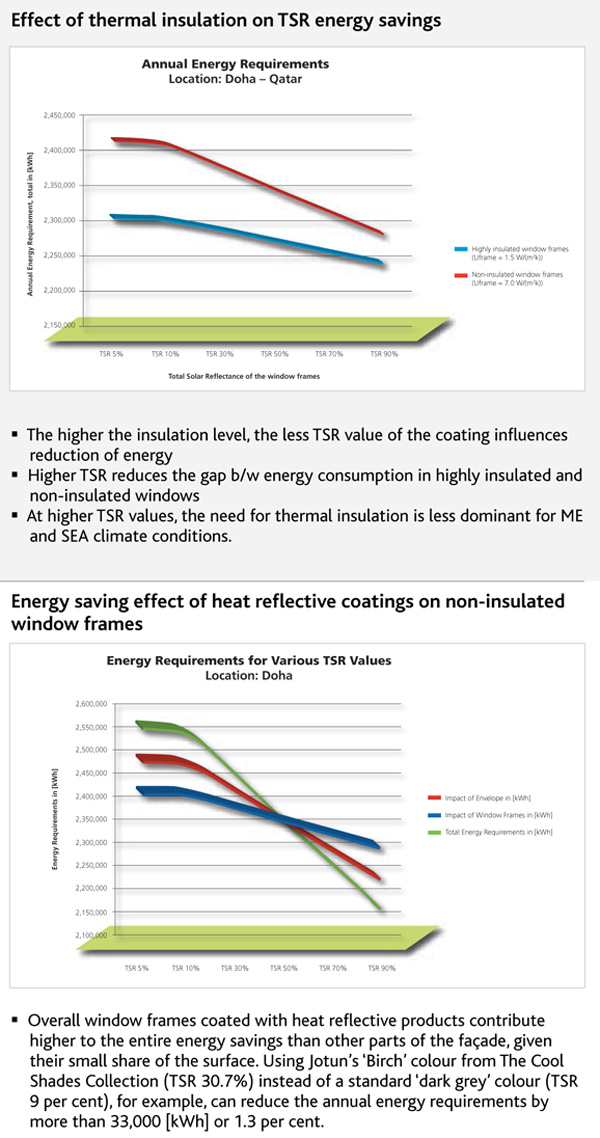

Aside from corrosion protection and adding aesthetic value, powder coatings also deliver functional benefits with heat reflection being one of the features. Heat reflective coatings can be produced in both powder and liquid form; they contain special pigments that improve Total Solar Reflectance (TSR) of the coated components – a fraction of solar energy reflected by the surface. In concept, the higher the TSR, the more heat is reflected and the cooler the surface remains. When applied on roof elements, external walls and on low-insulated window systems (typical solution in the Middle East region), TSR paints and coatings reduce heat transfer inside the building. In hot climates with the dominance of cooling requirements, it results in lowered energy consumption. By reducing the temperature of exterior surfaces, TSR materials can assist in lowering air temperature due to heat-transfer effect, which in turn helps to mitigate UHI effect.

Recent studies show that the application of heat reflective coatings on aluminium window frames can bring up to two per cent overall annual energy savings in the Gulf and South East Asian regions, while only adding a fraction to the overall project cost. Across hot climates, where typically low-insulated window systems are used, metal frames absorb enough solar energy to heat interior parts up to very high temperatures. Cases when human skin comes in contact with such hot surfaces for a prolonged period of time can lead to serious burns and skin damages. The use of heat reflective finishes helps in minimising such risks.

Quest for innovation

Liquid coating producers have placed strong focus on the efforts to reduce VOCs. While they are striving to move towards solvent-free products, they are also working to advance performance of waterborne systems to provide similar or even better corrosion protection than solvent-borne coatings. Another important direction they are taking is to reduce the use of aromatic solvents, which are dangerous for health and have a high negative impact on the environment.

One common path that the industry is looking to follow is the reduction of the amount of materials used in the coating process itself, while still achieving a high quality finish. The principle behind this direction is that the use of fewer materials helps reduce carbon footprint. Another important drive towards sustainability in the industry is to increase durability of the material – to prolong the life time of the coated surface, avoid repairs and reworks. Architectural powder coatings with enhanced durability and corrosion protection for example, are gaining increasing popularity in commercial, residential and infrastructure projects.

Assuming greater responsibility

In conclusion, being part of the paint and powder coatings industry has given us the realisation that our products are used in construction projects and their impact on the environment, human health and economics, can be quite substantial. With this in mind, we believe that it is our responsibility to ensure the continuous development of solutions and technologies that support Green Building initiatives and standards. Sustainability remains a driving force in our quest to be green and reflects the industry’s commitment to making construction and the Earth itself a cleaner and environmentally safer place to live in.

The writer is Global Product Manager, Jotun Powder Coatings.

When Jotun introduced its new line of heat-refl ective architectural power coatings, which it claimed is energy-saving and environmentally friendly, the company commissioned a German sustainable architecture consultancy and reaserch fi rm to conduct a study on the impact of the Total Solar refl ectance (TSr) values on the users’ comfort and energy performance of buildings. Here is a summary of the results.

Copyright © 2006-2025 - CPI Industry. All rights reserved.