What ails our industry – Part II

In this, the second of a six-part series, George Berbari turns his attention to what he describes as the less-than-salubrious state of affairs concerning air-cooled chillers and decorative and ducted-split systems

- By Content Team |

- Published: May 10, 2015

– By George Berbari

George Berbari, CEO of DC PRO Engineering

Over the years, air-cooled systems have received substantial negative publicity as performing in the range 1.4-2.0 kW/tonne, with an average value of 1.7 kW/tonne. They have also received negative reviews owing to their inability to withstand saline weather conditions – the deterioration of air-cooled condenser fins or micro-channel condensers, which necessitate a replacement every seven years – has been well-documented. They also suffer from air recirculation, in instances where the condensers are placed close to one another or close to a high parapet wall. In such situations, an ambient temperature in the low forties (in centigrade terms), say, mixes with the leaving hot air from the condenser and re-enters the condenser coil at temperatures sometime exceeding the high fifties (in centigrade terms), resulting in much higher power consumption and leading to the tripping of the compressor.

The ducted-split market is seeing second- and third-class brands claim ultra-high efficiency performance, even superseding the top four brands, and this is causing serious concern related to reliability and sincerity of data. The situation is so serious it requires independent certification bodies, such as AHRI (Air Conditioning, Heating & Refrigeration Institute) and Eurovent to test the units and confirm their performance.

None of the accredited labs are yet present in the Middle East, despite a serious attempt from AHRI to certify equipment at 46 degrees Centigrade with reduced or minimal tolerance; Eurovent allows -5% tolerance on capacity and -8% on EER, while AHRI allows 5% tolerance on capacity, 7.8% on EER and 10% on kW/tonne.

We have come up with the zero-tolerance test for centrifugal chillers, and I believe it is high time we applied the same to air-cooled ducted splits and chillers. In my view, Eurovent and AHRI ought to apply more stringent requirements, which would please the planet but, perhaps, not the manufacturers.

On the air-cooled chillers side, BTU meters and kWh meters for every chiller and every pump ought to be an essential aspect of every design, in order to allow for monitoring the performance of the equipment. I don’t see that happening, though, which begs the questions, “Why not, in an energy-conscious society?” and “Why are local regulations not calling for them?”

Despite all these facts and circumstances, air-cooled chillers, decorative or unitary systems, ducted splits and packaged units still constitute over 70% of the air conditioning market in the GCC. Is there something wrong in our thinking, or have we failed to find alternatives?

What makes them popular is the low cost associated with them, of course. For instance, a 1.5 TR decorative split costs as little as USD 400 or 600 per TR to buy and install, making it the least expensive air conditioning system in the world and one that is within the reach of the poor segment of the population. It is for this reason that labour camps, site caravans and even low-cost housing and villas have opted for them.

Affordability is, of course, a virtue from a socio-economic development perspective, but is that the whole story? Can the region afford to have decorative splits running, from an energy management point of view, not to forget other aspects? For instance, are we not forgetting the associated costs related to the electrical system inside the house and the electrical infrastructure cost at site? And what about the cost for the electric utility from power generation, electric power transmission and distribution points of view?

Let’s go into the metrics of operating a 1.5 TR nominal capacity (or 1.3 TR actual capacity) decorative split. It typically requires 2.2-2.6 kW of power input, with an average value of 2.4 kW (1.85 kW/tonne of actual capacity). The internal electrical work inside villas and low-rise buildings is USD 330/kW, while the site-wide infrastructure cost – which includes the 132 or 230 KV substation, 11 or 22 KV distribution, transformers and utility connection fees – is around USD 450-USD 500/kW. The utility cost is around USD 2,200/kW, and this covers the power plant, the high-voltage distribution, the high-voltage transformers station and the typical 10-30% spare capacity required by the utility.

Hence, the humble 1.5 TR split unit, which costs just USD 600, has the following costs associated with it from a macro point of view:

- Internal electrical works: USD 400/kW x 2.4 kW = USD 960

- External site infrastructure: USD 475/kW x 2.4 kW = USD 1,140

- Utility infrastructure: USD 2,200/kW x 2.4 kW = USD 5,280

The total associated electrical cost is USD 7,380

The hidden cost, or associated cost, is almost 11 to 12 times more expensive than the cost of the air conditioning unit itself. The worrying aspect is that very few engineers, owners or developers fully comprehend the associated cost – simply put, they only see the tip of the iceberg.

And the costs don’t end there. I mean, what about the cost to the environment, where each kW of electricity emits more than 0.6 kilogrammes of CO2 in the GCC. A split unit, typically running for 3,000 hours per year at an average consumption of 1.4 kW/tonne, emits more than 2.5 tonnes of CO2 into the atmosphere of our already suffocating planet!

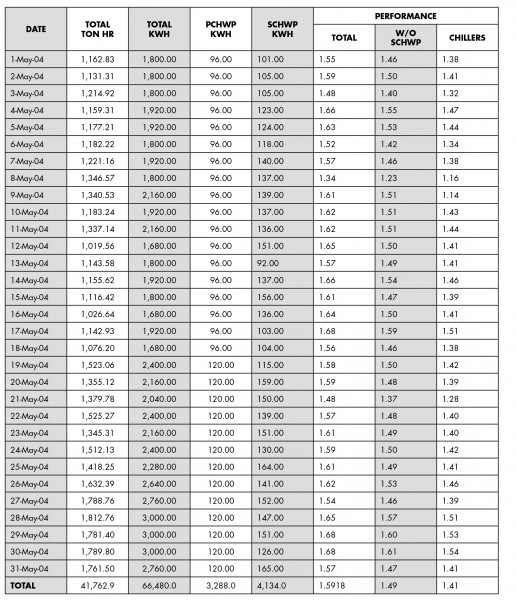

My obsession with real-life measurement has always led me to monitor performance, and I would like to share with you the data for a typical month (May), which represents the average annual performance of air-cooled chillers. (For the purpose of collecting the data, I considered a utility-grade equipment, which gave an average performance of 1.41 kW/tonne.)…

The writing is on the wall and deserves a vibrant response. The process of coming up with new high-efficiency standards, with the consensus of the majority of the heavyweight manufacturers, is taking too long and has soft targets, which will not help in improving efficiency.

A subtext to the drama is the issue of refrigerants. I am deeply concerned by the sight of the high volume of refrigerants that are pumped into air conditioning systems and by the massive leaks that occur during their operational lifetime. To date, I have not seen technicians carrying a receiver tank along with the pump-out unit. I have also not seen any leak-detection system associated with these units. If that were not serious enough, how many of us have seen technicians using refrigerants to blow open a clogged drain line? In the West, a technician caught doing so would have faced prosecution; it is high time we adopted such stringent measures and also insisted that all technicians be certified or trained. We need to act, and with speed. The GCC region consumes more refrigerant than the entire continent of Africa or the sub-continent of India, and we need to see the volume of use come down by a substantial margin.

Overall, I hope we will start seeing an end to our addiction for air-cooled systems sooner than later. And I hope we get to see more stringent regulations leading to a marketplace populated with more efficient units, and to a situation where the maximum power demand is 100 watts per square metre for all residential and commercial buildings; that would, in turn, hopefully compel the designer to optimise other system components in the house. For example, a 1.6 kW/tonne and efficient design of 40m2/tonne would translate to 40 watts/m2 for the air conditioning system, leaving only 60 watts for the rest of the components (appliances, receptacles, lighting, water heating, etc.), which would force the designer to use solar hot water heating and gas cookers, and reduce the lighting density as an example.

George Berbari is the CEO of DC PRO Engineering. He can be contacted at gberbari@dcproeng.com

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.