Since the lowest GWP products tend to be flammable, typically falling within the ASHRAE 2L category, the industry is faced with the dilemma of using the lowest GWP fluid and the attendant degree of flammability, or accepting a higher GWP refrigerant but with non-flammability. Stuart Corr discusses the finer points of the issue.

– Stuart Corr

By now we are all aware that regulation of fluorinated refrigerants is in place in Europe through the Mobile Air Conditioning (MAC) Directive for automotive air conditioning, or the F-gas Regulation for all other refrigerant applications. Over the last few years, the chemical manufacturers have been looking to develop reduced GWP products that are capable of meeting the requirements of these regulations, while maintaining the high levels of safety and efficiency we have come to expect from hydrofluorocarbon (HFC) refrigerants.

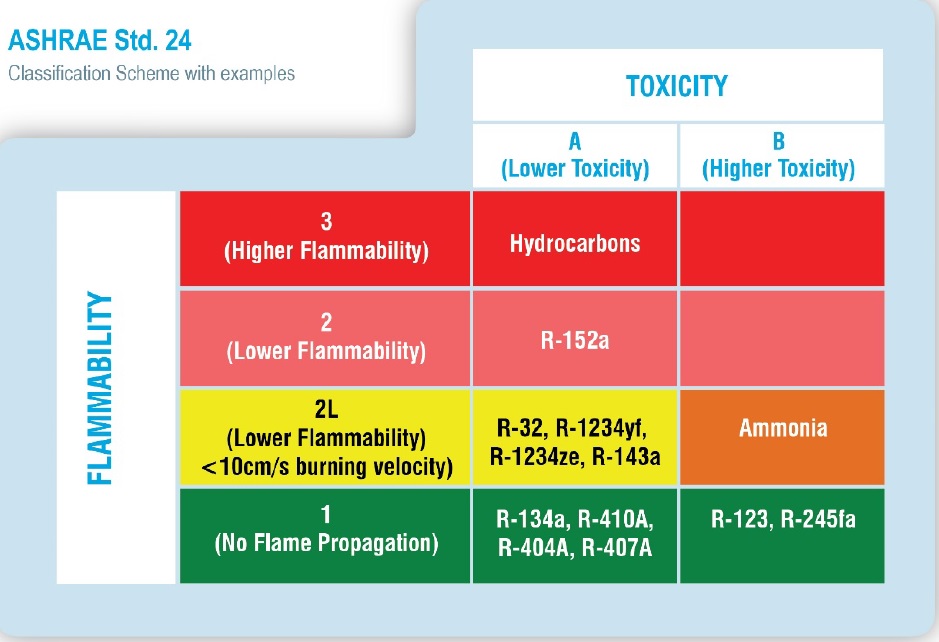

Figure 1

We are in a position where the refrigeration and air conditioning industries have a number of options available to them across the range of application sectors, and many of the equipment manufacturers have active programmes to thoroughly investigate the performance and reliability of these alternatives, and to optimise system performance based on the properties of the new fluids.

As with many of the higher GWP products they are to replace, for example R-404A, many of the new alternatives proposed are blended HFCs. The building blocks for these alternatives include hydrofluoroolefins (HFOs) as well as the more familiar lower GWP fluids, such as R-32 and R-152A. All of these components are flammable, falling into the ASHRAE 2L safety category. While they can be blended with non-flammable components in order to achieve non-flammability, for the majority of air conditioning and refrigeration applications, it is an unfortunate fact that the lowest GWP products will tend to be flammable to a degree, mostly falling within the ASHRAE 2L category.

[div class=”text-box text-box-left” style=”background-color: #FF5733; color: #FFFFFF; “]

R-22 is the most commonly used refrigerant in the Middle East, but it is rapidly approaching the end of its life under the Montreal Protocol. However, matching the performance of R-22 with alternative refrigerants is particularly challenging in hot climates, in part because many of the alternatives have a lower critical temperature, resulting in a drop in performance at very high ambient conditions. R-410A is a non-flammable, established and efficient alternative to R-22 in many application sectors, including HVAC. There are lower GWP alternatives with good critical properties, including R-32 and blends of R-32 with other HFCs, that may be more suitable for hot climates. However, all of these alternatives are mildly flammable and, in some cases, would require equipment redesign and additional safety measures in some applications. Retraining in the correct handling of these fluids would also be required in order to ensure safety in use. In choosing an alternative for R-22, we need to weigh safety, efficiency and environmental impact for each application sector. Currently, the priority in the Middle East remains to reduce ozone depleting refrigerants. When weighing the refrigerant options available, companies should consider the two possible courses of action: using a proven non-flammable HFC blend, such as R-410A, or opting for a newer and lower GWP refrigerant with a degree of flammability. Regardless of the choice, updated standards and industry regulations should provide information on safety and best practice for different alternatives to R-22 in the Middle East.

[end-div]

The industry is then faced with a choice – to use the lowest GWP fluid and accept a degree of flammability or to accept a higher GWP in order to maintain non-flammability. Central to this choice is how to meet the GWP regulatory requirements while maintaining a high degree of safety?

In some circumstances, the choice is made for us by the regulations. For example, the MAC Directive requires use of refrigerant GWP below 150, and with the exception of CO2, there are no viable nonflammable candidates. Similarly, looking ahead to alternatives for R-410A in smaller (< three kilogramme charge) single-split air conditioning systems, the F-gas Regulation imposes a GWP limit of 750 and, again, there are no viable non-flammable candidates identified to date with R-32, and blends based on R-32, coming to the fore.

The first step in introducing a refrigerant is to determine the flammability and toxicity classification for the fluid. This is most commonly done through the internationally recognised ASHRAE classification system (Figure 1).

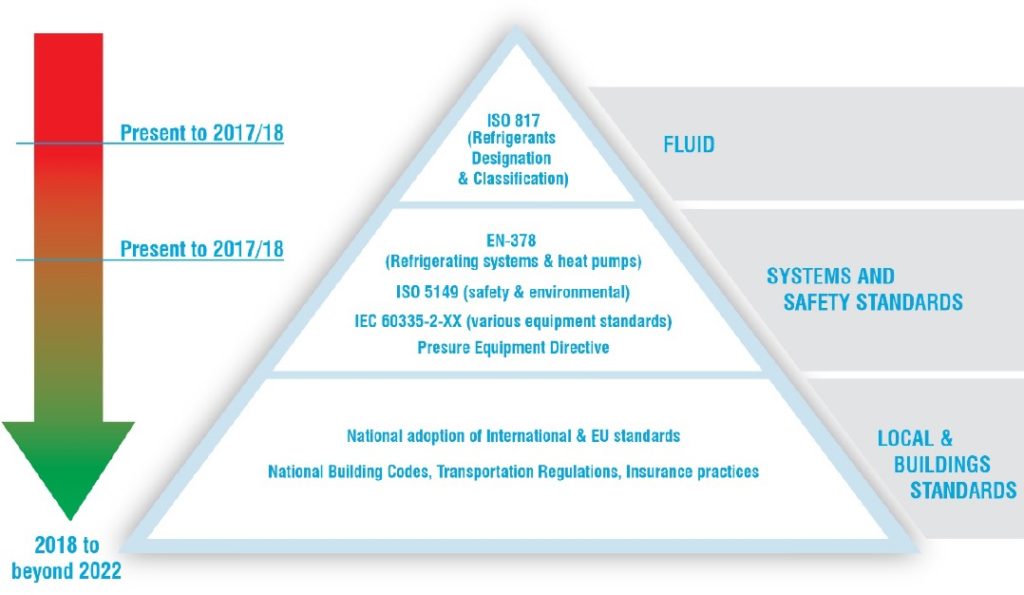

Whilst this process is essentially complete for the MAC sector, the stationary applications are more complex. In order to understand the range of applicability of a refrigerant, it is necessary to consider a range of national and supra-national regulations. These regulations principally relate to the safe use of the refrigerant in a range of application sectors and govern aspects of equipment design, location and installation requirements. These regulations are generally based on the refrigerant safety classification or the data used to obtain that classification, for example, flammability limits.

While highly flammable hydrocarbon refrigerants and the less-flammable ammonia have been used for a number of years, most in relatively small domestic refrigeration applications or in industrial applications, the industry has generally relied on the use of non-flammable fluids to ensure a high degree of safety across a wide range of applications and operating environments. Many countries have regulations that prohibit the use of flammable refrigerants in many applications.

In order to understand the range of applicability of a refrigerant, it is necessary to consider a range of national and supra-national regulations

With the introduction of the 2L flammability category in 2010, it was recognised that there was a group of refrigerants that, while flammable, had the potential for lower risk in use than the more flammable hydrocarbons. While current standards and codes provide safe boundaries for the use of flammable refrigerants, most do not yet recognise the 2L category. Accordingly, if 2L refrigerants are to be used in current equipment and environments, they must be treated as if they were category 2. Under the current EN378, the maximum charge for propane in a wall-mounted indoor split air conditioning unit in a 3-squaremetre room is around 0.23 kilogrammes, while that for R-32 is around 3.08 kilogrammes. While this is still potentially very attractive for 2L fluids in some application sectors, there are other regulations, many of them at a national level, that place more severe limitations on their use. For example, both Italy and France currently prohibit the use of flammable refrigerants in room air conditioners.

Figure 2

EN378 is currently under revision to incorporate and provide new limits for the 2L classification, and is expected to be issued in October or November this year.

If we are to exploit many of the low GWP fluids to their maximum extent, we need to understand how widely applicable they are, and we need to understand how regulations should be amended to incorporate the new classification, while critically maintaining end-user and practitioner safety. Figure 2 provides an overview of some of the regulations and codes that are either under current review or which may need to be reviewed in order to address 2L refrigerants.

Any amendment of standards and building codes must be undertaken with a significant degree of conservatism with respect to safety. Furthermore, many of these codes and standards are only reissued on a three-yearly or so basis, and with a degree of interdependence. As a result, it will be a number of years before the potential for 2L fluids to provide low GWP solutions across a range of sectors will become clear.

CPI Industry accepts no liability for the views or opinions expressed in this column, or for the consequences of any actions taken on the basis of the information provided here.

Stuart Corr is Techno Commercial Director, Mexichem. He can be contacted at info@mexichem.com.

Copyright © 2006-2025 - CPI Industry. All rights reserved.